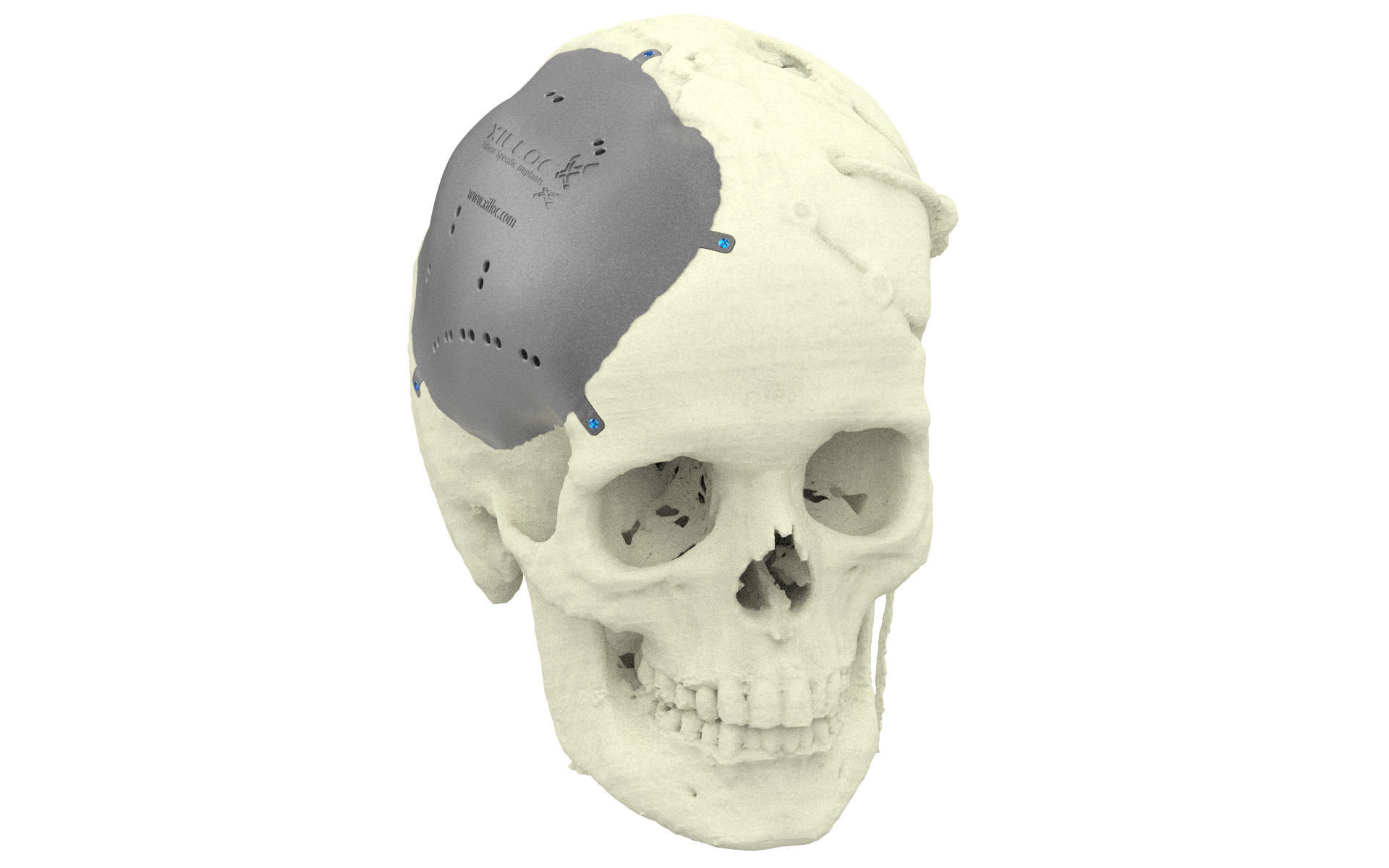

The world’s first 3D printed titanium skull implant

The world’s first 3D printed complete jaw implant

In 2006, young biomedical engineer Maikel Beerens (aged 21) did his intership on the topic of “Custom-made Implants” at Maastricht InstrumentsB.V and IDEEthe engineering department of the Maastricht University Medical Centre+ (MUMC+). In cooperation with the department of Cranio-Maxillofacial and Plastic Surgery, who had been working with custom-made implants from around 2003, they developed a method to preoperatively design and 3D print, patient-specific implants, based on a computer tomography scan of the patient. The first 3D printed titanium skull implant went around the world. Everyone in the medical additive manufacturing industry knows it. This kind of implants have been implanted very successfully ever since. For his thesis he was awarded the Fontys Technology Award, for best thesis in the Netherlands.